Multilith 1250: More Progress, Slow Going

So it’s been over a month since my last update, and here’s where I’m at. Paper is still not feeding through the press smoothly (thankfully I bought a few boxes full of ‘test paper’ for this exact purpose). So far the only part I’ve replaced is the 20-year-old blanket. I couldn’t get the upper feed rollers off, so I didn’t bother ordering new ones yet. I’ll keep trying, although I don’t think that is actually part of the problem.

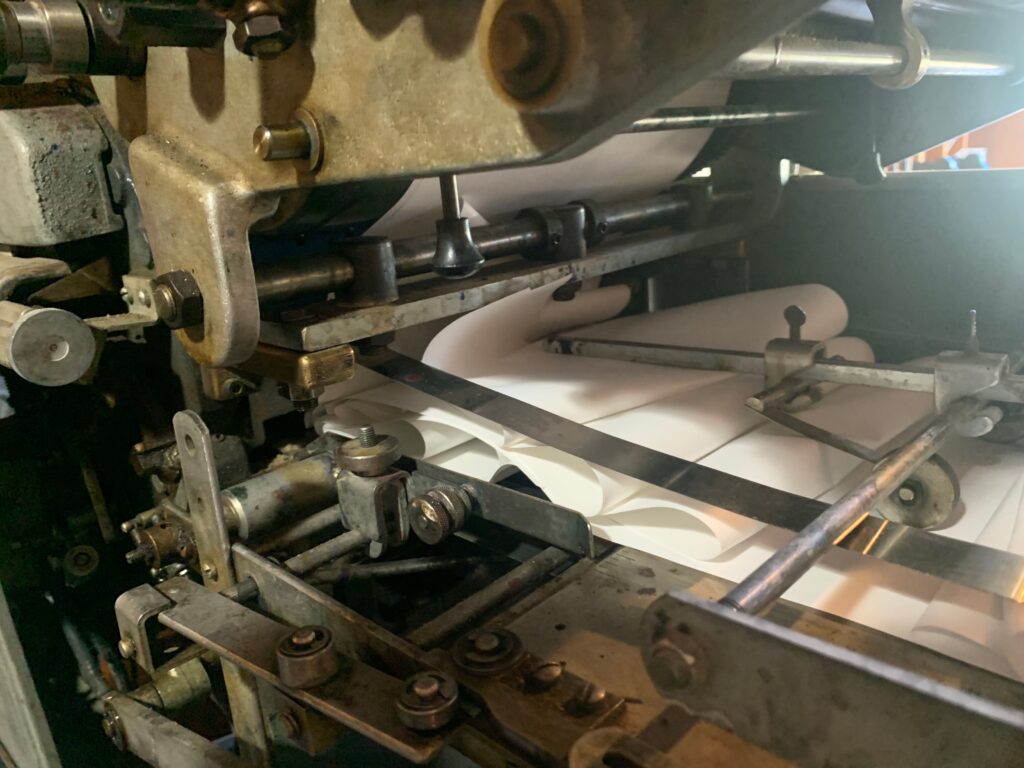

This weekend I looked at the registration board on the press, and have tried adjusting all the alignment guides that are supposed to straighten the paper out, line it up with the plate master, before feeding it into the image rollers. I think I’ve got that set properly for the moment, at least as far as I can tell. But for some reason paper still isn’t getting pulled into the cylinders properly on each cycle, and so I end up with multi-sheet pile-ups in a matter of seconds.

At first I thought the vacuum was feeding sheets onto the registration board too quickly, faster than the jogger and imaging rollers could handle. I made sure to watch some more videos to see if my press’s timing was off. Near as I can tell, though, the vacuum is working at the right pace – it pulls a new sheet onto the registration board just as the previous sheet is supposed to get pulled into the press. But watching my press in action I can see that the issue is the paper not being picked up by the rollers properly. So that’s the next thing to figure out. My hope in replacing the blanket was just that the old one was so smooth from who knows how many years of use and neglect, that it was just not capable of grabbing the paper. So far the new one hasn’t helped in that regard.

Worst case, from the looks of it, is that the roller that’s supposed to pull the paper toward the imaging rollers needs to be replaced, or re-rubbered. Gotta figure out the name for that roller so I can look them up and see how much it might run me. Of course first I need to see how hard it’s going to be to pull it out, it’s not as accessible as most of the ink and water rollers on top of the press. Update: Looks like it’s the Lower Feed Roller, available new or refurbished from Printers Parts for a little over $200.

Also, I swear I’m smelling rubber burning when I run the press. Not sure if that’s a direct result of the paper jams, or if there’s a belt failing somewhere that’s causing the jams, so I’m going to look at all of those and start replacing them as well. Again, they’re old, and could stand to be replaced either way.

It feels like I’ve been dragging my feet on getting this press up and running, and yeah, I kind of have. It’s really discouraging to find something else going wrong with it every time I turn it on and try to fix something. One thing that gets in my way is that I haven’t yet found an online forum for people who are familiar with these particular machines, so there really isn’t any place to find answers to the problems I’m having. I am learning more about how to set it up and maintain it, though, and that’s not a bad thing.

Onward!