Garage Update: November

Hey, gang! Just wanted to put up a quick update of a couple things that have been happening out in the Garage this month.

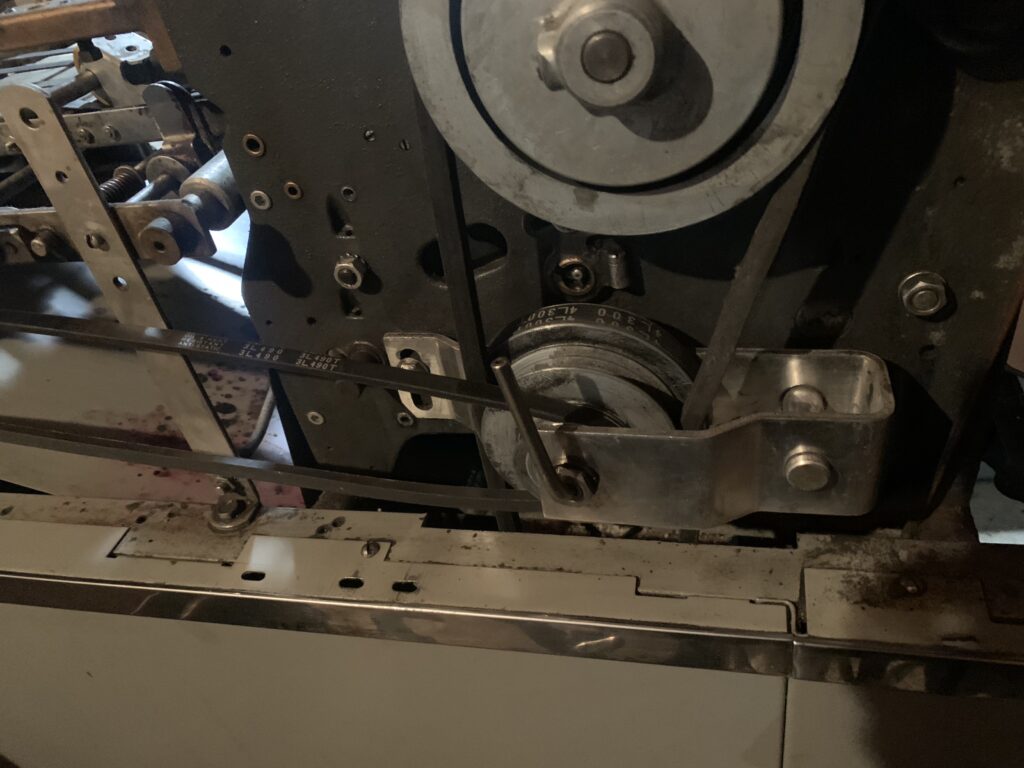

I managed to repair a couple small things on the press that have been bugging me for a little while, and a couple things I didn’t even know were busted until very recently. Probably the biggest thing has been replacing most of the rubber belts that drive the whole printing mechanism! There are four belts in total on this press, three on the main pulley next to the master cylinder, and another one running the air pump. I pulled all four of them with the help of this 1250 Troubleshooter* book I picked up on eBay last week. It showed how to remove the main pulley and gave tips on finding comparable replacement belts if you can’t find OEM belts.

A quick trip to the auto parts store got me the belts I needed, and replacement went pretty smoothly once I figured out the order I needed to follow when slipping them back onto the pulleys. Two of the upper belts were pretty shredded, cracked and splitting, but one looked much newer and was still in decent shape. The air pump belt was also just a mess. I’m not sure, but I think at least one of these was the cause of the burning rubber smell the last few times I ran the press.

Next was replacing the hinges on the doors of the cabinet below the press. Not a huge deal, but considering I was the one who totally messed them up when I initially picked the press up and brought it home, it was important to me to restore that back to original working order. I worried it was going to be a challenge finding compatible hinges, but taking the old ones with me to the hardware store proved the right move. I was easy to match up the hinge size and hole spacing with no problem, and the new ones went in nice and smooth.

And finally, I figured out where to install the Set-Off Powder sprayer that was included with the press. I hadn’t thought much of this accessory, really. It wasn’t a high priority for me to get it working. But I looked them up, and actually it looks like this will be a really useful thing. What it does is, when a freshly printed sheet comes off the impression cylinder and gets dropped into the receiver tray, this device sprays out a small amount of food-based dust onto the page, so that it creates a microscopic buffer for the next sheet to sit on. This prevents ink from transferring onto the back of the next sheet off the press, and keeps the prints nice and clean. It took me a good amount of poking and prodding on the press before I finally found the spot where the actuator switch needs to be installed in order to trigger properly each time a sheet goes through the print cylinders. But now that I have that figured out, I don’t see any reason not to go ahead and set the rest of the set-off system up to use it, especially when I’m printing a lot of large solid areas (which is I guess most of my comics, really).

So anyway, that’s about it for the Press news this time. I did also spend a good couple hours and a couple rolls of paper towels spraying and cleaning all of the safety plates that cover the outside of the press, and that’s in anticipation of giving the guy a good fresh paint job. Still waiting on arrival of a couple replacement Upper Pullout Rollers, and then I can get the press fully reassembled and start running some test prints!

*I’m building a pretty good library of Multilith 1250 documentation, service guides, and user’s manuals.